|

|

Build Your Online Product Catalogs?

| Product Name: |

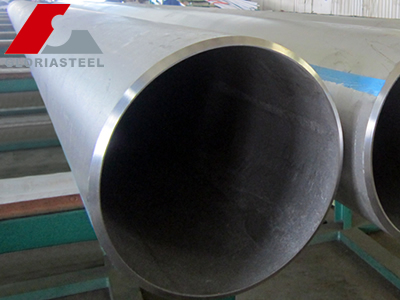

Super-ferritic stainless steel Grade TTS439

|

| Supply Ability: |

|

| Related proudcts |

stainless steel, super-ferritic, |

| Specifications |

Conventional Products |

| Price Term: |

|

| Port of loading: |

|

| Minimum Order |

|

| Unit Price: |

|

|

Super-ferritic stainless steel Grade TTS439

Technical advantages:

Producing advantage: Equipped with large-scale, advanced and high efficient equipments, we can produce a series of super ferritic stainless steel product is in different grades and specifications, and meet the requirements of market.

Quality of products: The process which use hot metal as main part of materials to produce super ferritic stainless steel can reduce the unnecessary elements to lowest level. Using VOD decarburization and denitrifying process can get the lower content of carbon and nitrogen.

Application of Super Ferritic Stainless Steel Industry

The industry of automobile exhausting system: We have established long term cooperation with end users and service centers which work at automobile exhausting tubes and pressed parts.

Conventional Products

Steel grade Grade Specifications

Thickness Width mm Weight MT Standard Application

400 series 439

TTS439 2B/2D Surface: 0.3-3.0mm

BA surface: 0.2-1.5mm 2B/2D Surface:

1000-1280

1000-2000

BA surface: 1000-1500 6-15MT ASTM/ASME

Q/T 012-2011 Apply to elevator, kitchen appliance

Chemical Composition

Grade Mass Percentage (%) MAX

C Si Mn P S Cr N Mo Others

439 0.030 1.00 1.00 0.040 0.015 17.5-18.5 0.030 - Nb+Ti:4C-0.75

Physical properties

Grade Density (g/cm3) Elastic modulus GPa Linear expansion coefficient 10-6/K20-100C Themnal conductivity W/m K 100C J/Kg k Specific heat 20C Resistance rate (UM cm) Magnetism

439 7.70 200 10.4 23.1 460 60 Qualified

Mechanical Properties

Mechanical properties at ambient temperature

Grade Yield strength RP0.2(***) Tensile strength Rm(***) Elongation A(%) Hardness HRS Hardness HV Bending test

439 ¡Ý205 ¡Ý415 ¡Ý22 ¡Ü88 ¡Ü183 Qualified

Welding Properties and Notice:

Low carbon and Nitrigon, Titanium and Niobium added, high corrosion-resisted performance on welding parts.

Difficult for Fusion wedding and etter for filler wire welding.

Low thermal expansion coefficient-high heat conduction and small defor |

| Company: |

Gloria Steel Limited

|

| Contact: |

Mr. Toby Tan |

| Address: |

C38C Room, City Plaza Chang'an Town |

| Postcode: |

523850 |

| Tel: |

+86-769-85325956 |

| Fax: |

+86-769-82380569 |

| E-mail: |

|

|

|

|